Need for mechanical ventilation has over ages increased in proportion to the envelope size of the buildings. A common way of quantifying the ventilation rate is by specifying in terms of the quantity as multiple of the volume of the enclosed space per unit time. Say if the ventilation system displaces an equivalent to five times the volume of an enclosed space in an hour, it is specified as 5 Air changes per hour (ACH)

Depending on the applications, the ventilation rate varies which decides the amount of air that is to be fed and extracted.

Applications of mechanical Ventilations

- Under ground constructions

- Kitchen & associated units

- Chemical plants

- Water treatment plants

- Industrial process units

- Hospitals

- Pharma units

- Toilet ventilation

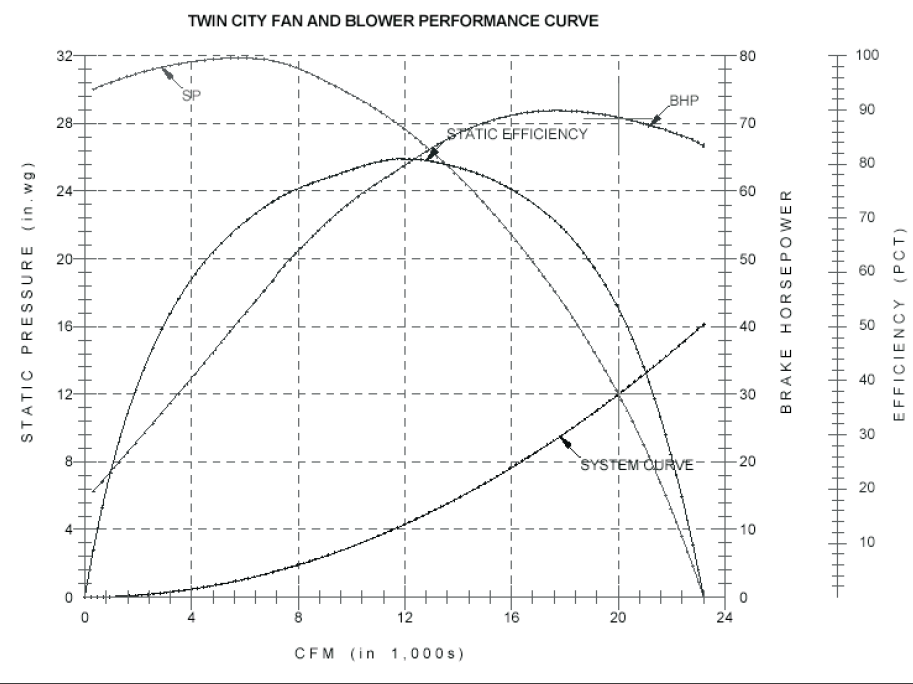

Designing a system in such a way that the fan runs at its best efficiency point is one of the important aspect of ventilation system design. Hence calculating the system pressure for the designed air flow and selecting a fan that has its best efficiency point at that condition is essentially an engineer’s work.

Not only does the fan operating at the best efficiency point and selecting an efficient motor matters, the over all system efficiency depends on the air distribution pattern as well. A well engineered design shall ensure optimum performance and energy efficiency at lowest life cycle cost.

A well engineered ventilation system will ensure

- Adequate ventilation rate

- Ensuring the proper extract locations

- Maintain required room pressure

- Optimum overall energy efficiency

- Economic sizing of duct works

- Best Efficiency point for the fans

- Minimise noise level

- Durability and reliability

While as a practice, toilets, kitchens etc maintain negative pressure by exhausting more air than the make up air, for obvious reasons and if the adjacent area is air conditioned, any deviation in the ventilation air flow quantity will have alarmingly heavy impact on the energy bills and performance due to increased infiltration to the air conditioning system. These are various observations in the industry due to poorly engineered HVAC systems.

We take all effort to provide the client, a system that performs with lowest life cycle cost..